DREAM IT · BELIEVE IT · ACHIEVE IT

There are several options to mitigate the problems of harmonics in power systems. Unfortunately, there is no solution that suits all applications. The key is to detect and choose the right option for your needs. Failure to reduce these unwanted electrical currents can lead to problems ranging from overheating of conductors and neutral transformers, to inefficient operations of electronic equipment. The unexpected alarms of the variable frequency Drive (VFD), the problems of PLC and the computer blocks are common problems that come from an excess of harmonics in the distribution system.

To determine the best solution to mitigate unwanted harmonics, start by investigating the equipment that you suspect generates the most harmonic currents. Most of the time they are variable frequency actuators (VDF). Use measuring equipment to measure and analyze the frequencies and amplitudes of the harmonics. It is much simpler than it sounds. The electrical quality analyzers and recorders measure and record these values, calculate the distortion of the 60 Hz sine wave created by the harmonics and allow the download of data to a computer, in order to perform a deeper analysis. The key parameter that calculates this analysis equipment is the total harmonic distortion (THD). The TDH is calculated for both voltage and current. Once the measurement process is complete.

What is the best way to proceed with the measurement of the necessary values? Measuring only the amount of THD at a point in time and acquiring a filter to mitigate these harmonic currents is probably not the best solution. The reason is that the frequency and magnitudes of the harmonic currents that are being created by the VFD normally vary as the load changes in the inverter. For example, a given VFD can create many harmonics of a relatively low magnitude when charged lightly, but produce more prominent harmonic frequencies with heavy loads. If the harmonic data is recorded only once for a relatively short time, it is likely that the data you need will escape.

Harmonic filters, shutters and other devices used to mitigate harmonics were designed to work with certain harmonics and under certain operating conditions. When selecting a harmonic filter to mitigate the harmonics generated while the VFD is lightly charged, it is most likely that you end up making an error when buying the harmonic filter. You may find that the most serious problems are generated at other times during the operation of the plant.

If you want to mitigate problems with harmonics, follow these steps:

1. Identify any suspicious non-linear equipment (VFDs are typical) that you believe are causing unwanted harmonics to flow into your distribution system.

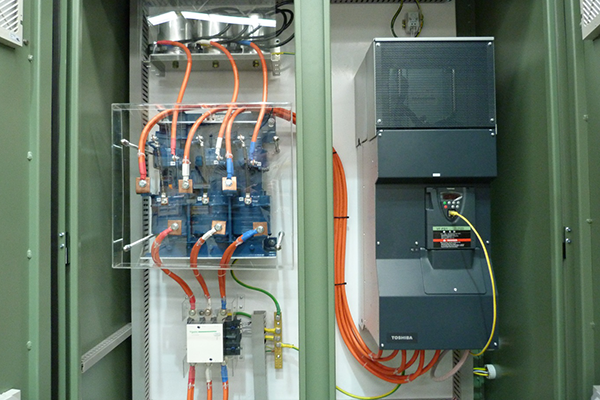

2. Configure an analyzer or recorder of the quality of the electricity to record the data. Connect the tool at the point where the VFD connects to other loads in the system. This point is what is referred to as common coupling point (PCC) in industrial facilities. Although some recorders may be permanently installed, it makes sense to use a connected portable analyzer and place it securely within the appropriate electrical cabinet for the duration of the record study.

3. Always make sure to maintain the electrical safety precautions when connecting and disconnecting this type of equipment.

4. Record the data for at least one plant cycle to ensure that your data captures the events of the most severe harmonics. Obtain records of the operations and processes of the plant during this cycle and compare them with your recorded data.

5. Download the data to a PC to proceed with its analysis with the analyzer software. Next, observe the harmonics created at different times during the operation of the drive. Compare the data of the harmonics with the operational data of the plant. Ask questions, such as: "During which events and operations of the plant create the greatest distortion of the harmonics?" "What is the output load of my VFD at that time?" This will probably be the operating point of the VFD in which the harmonics will be corrected.

The IEEE recommends that the total harmonic distortion (THD) of the fundamental frequency of 60 Hz in this PCC does not exceed 5% voltage. To apply a corrective action,

6. If possible, try to relate any problems of the plant experienced during the registration of harmonics data with THD values and harmonic levels at that time. For example, if a PLC produces a false high temperature alarm in the equipment at the same time that the load changes in the VFD and a large motor starts in the plant, you may have discovered your harmonics problem. Your answer may be the application of a filter that has been designed for that particular VFD load.

7. Finally, work with the VFD manufacturer who has the problem to choose the best way to mitigate the harmonics. Through a series of questions and an engineering analysis, your VFD provider will help you determine the best solution, and will provide it in order to mitigate unwanted harmonics.

DREAM IT · BELIEVE IT · ACHIEVE IT

© 2021 Jiangsu LTEC Electric Co., Ltd. All rights reserved.苏ICP备11085855号-2  苏公网安备32058302002386号

苏公网安备32058302002386号